OEM Combiner Box: Streamlining Solar Power with Innovative Manufacturing Solutions

2026-01-01

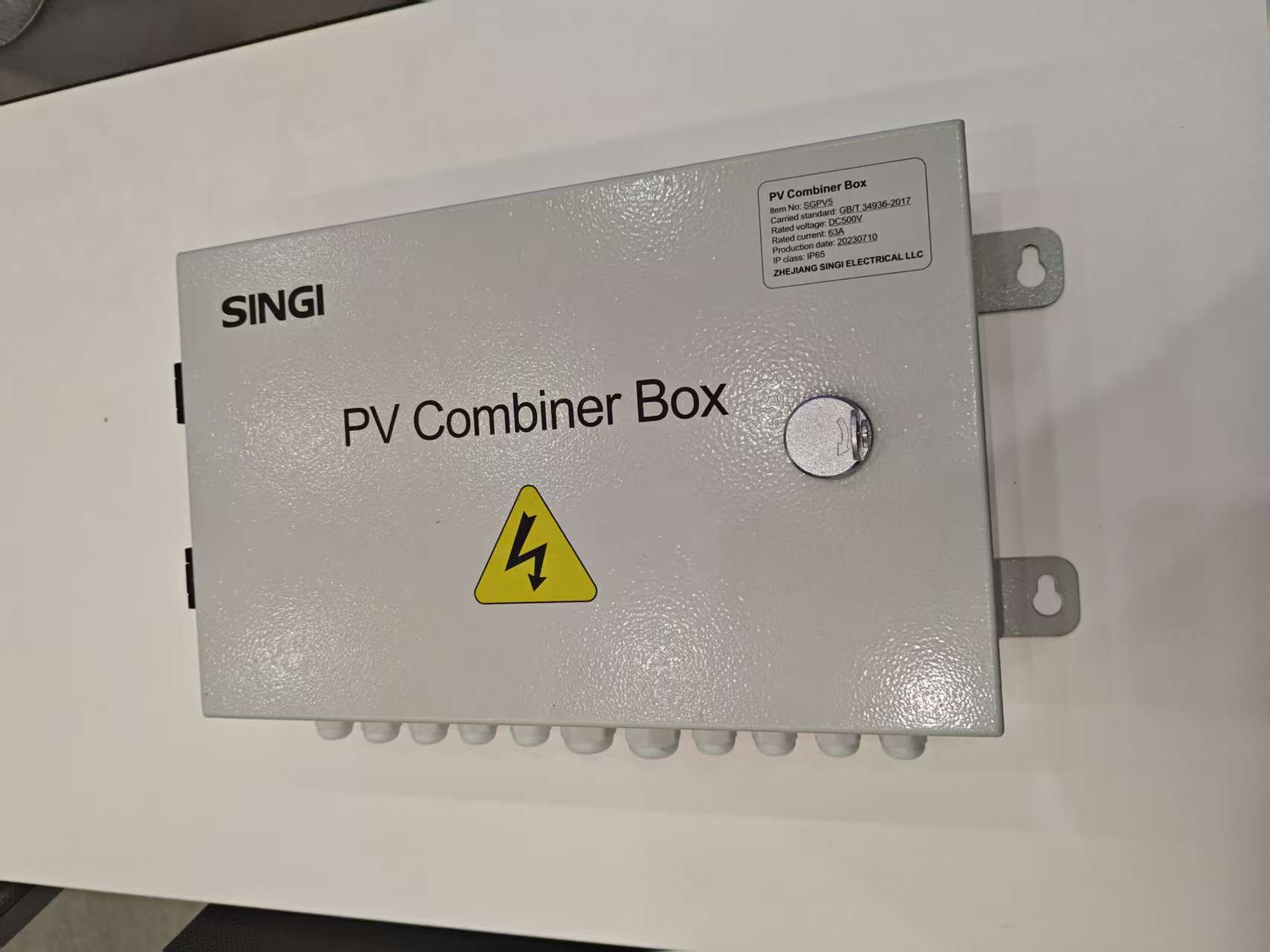

In the fast-evolving world of solar energy, efficiency and innovation are key to maximizing power output and reducing costs. At the heart of this transformation lies the OEM Combiner Box, a critical component designed to streamline solar power systems by integrating cutting-edge manufacturing solutions. This blog explores how these advanced boxes are revolutionizing the industry, offering enhanced reliability and scalability for projects of all sizes. Dive into the details with SINGI, a leader in providing tailored solutions that push the boundaries of what's possible in renewable energy. Join us as we uncover the secrets behind smarter solar setups and the impact of precision engineering on a greener future.

Revolutionizing Solar Integration with OEM Combiner Box Solutions

The adoption of OEM combiner box solutions is fundamentally transforming how solar arrays are integrated into energy systems. These custom-designed units streamline the consolidation of multiple strings, reducing installation complexity and boosting overall efficiency. By partnering directly with manufacturers, projects benefit from seamless compatibility and tailored configurations that adapt to specific site conditions.

What sets these solutions apart is their ability to incorporate advanced monitoring and control features right out of the box. Real-time data collection on voltage, current, and temperature not only enhances safety but also provides actionable insights for maintenance. This proactive approach minimizes downtime and extends the lifespan of solar installations, giving operators a clear edge in managing renewable assets.

Looking ahead, the integration of smart technologies like IoT connectivity and predictive analytics is pushing boundaries even further. These combiner boxes are evolving into intelligent hubs that optimize energy flow and respond dynamically to grid demands. By embracing innovation at the component level, the solar industry can achieve greater reliability and scalability, paving the way for more robust renewable energy networks.

Precision Engineering for Enhanced Solar System Performance

In the dynamic landscape of renewable energy, solar power systems stand out not just for their environmental benefits, but for their ability to deliver consistent, high-performance electricity. Precision engineering plays a pivotal role in this arena, focusing on meticulous design and manufacturing processes that optimize every component, from photovoltaic panels to inverters. By ensuring tight tolerances and advanced materials, this approach minimizes energy losses, enhances durability against weather extremes, and boosts overall system efficiency, making solar installations more reliable and cost-effective over the long term.

One key aspect of precision engineering involves leveraging cutting-edge technologies like computer-aided design and automated production lines to create solar panels with uniform cell alignment and minimal micro-cracks. These refinements lead to improved light absorption and reduced hotspots, directly translating to higher energy yields. Additionally, precision in mounting systems and tracking mechanisms allows for optimal sun exposure throughout the day, further maximizing power generation without compromising structural integrity or safety.

Beyond the technical specs, adopting precision-engineered solutions fosters innovation in solar applications, such as integrating smart sensors for real-time monitoring and predictive maintenance. This not only extends the lifespan of solar systems but also enables seamless integration with other energy sources, advancing toward a more resilient and efficient grid. Ultimately, by prioritizing precision, the solar industry can accelerate the transition to sustainable energy, offering robust performance that meets the growing demands of households and industries alike.

Custom Manufacturing Approaches to Simplify Solar Installations

Tailored production methods are reshaping how solar systems are deployed, moving away from one-size-fits-all solutions to designs that adapt to specific site conditions. By leveraging advanced fabrication techniques, companies can now create components that integrate seamlessly with diverse roofing materials or architectural styles, reducing the need for complex on-site adjustments. This shift not only accelerates installation timelines but also enhances system durability by minimizing potential points of failure introduced during assembly.

One standout example involves modular panel arrays that arrive pre-wired and ready for quick mounting, eliminating hours of labor typically spent connecting individual units. Additionally, custom brackets and mounting hardware can be engineered using 3D scanning and printing technologies to ensure a perfect fit for irregular surfaces, such as curved roofs or historic buildings. These innovations make solar accessible in previously challenging environments, broadening the market while lowering overall project costs through streamlined workflows.

Beyond hardware, software-driven customization plays a crucial role, with digital tools simulating installations to optimize component placement and energy output before any physical work begins. This proactive approach allows installers to address potential obstacles in the planning phase, further simplifying the process and boosting customer confidence in adopting renewable energy solutions.

Innovative Design Features That Boost Energy Harvesting

In the realm of energy harvesting, cutting-edge design features are revolutionizing how we capture and utilize ambient energy, pushing the boundaries of efficiency and sustainability. For instance, advanced microelectromechanical systems (MEMS) now integrate piezoelectric materials that convert vibrations from machinery or vehicles into electrical power, enabling energy generation in environments where traditional sources might falter. This approach not only maximizes energy recovery but also enhances the lifespan of devices by reducing reliance on external batteries or frequent maintenance, making it a game-changer for applications from industrial sensors to wearable technology.

Another standout innovation involves the use of flexible, transparent solar cells that can be seamlessly incorporated into windows or building facades, allowing them to harvest sunlight without compromising aesthetics or functionality. These cells, often based on perovskite technology, are designed to operate efficiently under varying light conditions, even capturing diffuse or indirect light in urban settings. By expanding energy collection to previously underutilized surfaces, this feature fosters a more integrated and sustainable approach to architecture, supporting green building initiatives and reducing overall energy footprints in smart cities.

Moreover, the integration of thermoelectric generators into waste heat recovery systems exemplifies a clever design feature that transforms thermal energy into usable electricity. These systems are tailored to operate at low temperature differentials, making them ideal for industrial processes or automotive applications where excess heat is abundant. By optimizing material compositions and structural designs, such generators achieve higher conversion rates, turning what was once considered energy loss into a valuable resource, thus boosting overall system efficiency and promoting circular energy practices.

Streamlined Assembly Processes for Faster Solar Deployment

In the solar industry, every minute saved during installation translates directly into cost reductions and quicker energy access. Streamlined assembly processes have emerged as a game-changer, with innovations like pre-assembled racking systems and standardized mounting hardware. These approaches minimize on-site labor, cut down errors, and enable crews to complete projects up to 30% faster than traditional methods.

At the core of this efficiency is a shift towards modular design, where components are engineered for quick click-and-lock installation. For instance, some manufacturers now offer solar panels with integrated connectors that eliminate tedious wiring steps. This not only speeds up deployment but also enhances safety by reducing electrical handling during assembly.

Moreover, leveraging digital tools like augmented reality for real-time guidance on-site ensures precise placement without constant supervision. By combining these strategies, projects can accelerate from planning to power generation, making solar solutions more accessible in time-sensitive scenarios like disaster recovery or urgent grid expansions.

Future-Proofing Solar Arrays with Advanced Combiner Technology

The rapid evolution of solar technology means that today’s state-of-the-art arrays might struggle to keep up with tomorrow’s demands. Advanced combiner technology addresses this challenge by integrating smart monitoring and modular design, allowing systems to adapt as new panels or components are introduced. Instead of replacing entire setups, operators can upgrade specific sections, minimizing downtime and waste. This approach not only extends the lifespan of solar installations but also enhances their resilience against technological shifts.

Beyond adaptability, advanced combiners incorporate real-time data analytics to predict performance issues before they escalate. By analyzing voltage, current, and environmental factors, these systems enable proactive maintenance, reducing unexpected failures. This predictive capability ensures that solar arrays remain efficient and reliable over decades, even as energy needs grow. It’s a practical step toward making renewable energy infrastructure more sustainable and cost-effective in the long run.

Moreover, the integration of these technologies supports grid stability by managing power flow more intelligently. Advanced combiners can balance loads and optimize output in response to fluctuating demand, which is crucial as solar penetration increases. This flexibility helps solar installations stay relevant in a dynamic energy landscape, ultimately contributing to a cleaner, more resilient power grid for future generations.

FAQ

Its innovative manufacturing solutions provide enhanced durability and efficiency, specifically designed to handle diverse environmental conditions while simplifying installation.

By integrating advanced components that reduce energy loss and ensure reliable power distribution, it boosts overall system output and longevity.

It includes weather-resistant enclosures, easy-to-access terminals, and modular designs that allow for scalability and quick maintenance in solar arrays.

It tackles issues like component failure and complex wiring, offering streamlined solutions that cut down on downtime and labor costs.

Innovative techniques lead to higher-quality parts and assembly processes, ensuring the box meets stringent industry standards and user demands.

By optimizing energy flow and reducing waste in solar setups, it supports cleaner power generation and helps lower carbon footprints.

Solar installers and project managers gain from its user-friendly design and reliability, which enhance project efficiency and client satisfaction.

Ongoing research aims to incorporate smart monitoring features and improved materials for even greater efficiency and adaptability in evolving solar markets.

Conclusion

The OEM Combiner Box revolutionizes solar integration by providing tailored solutions that streamline the entire power generation process. Through innovative manufacturing approaches, these combiner boxes simplify installations and enhance system performance with precision engineering. Custom designs address specific project needs, ensuring that solar arrays operate at peak efficiency while minimizing setup complexities. This focus on adaptability and performance underscores how OEM solutions are transforming the way solar energy is harnessed and managed.

Advanced combiner technology incorporates features that boost energy harvesting and support faster deployment through streamlined assembly processes. These innovations not only improve current operations but also future-proof solar arrays against evolving demands. By integrating cutting-edge design with efficient manufacturing, OEM combiner boxes offer a robust, scalable framework that accelerates the adoption of solar power. This holistic approach positions them as essential components in driving sustainable energy solutions forward, making solar installations more accessible and effective worldwide.

Contact Us

Contact Person: Jack

Email: [email protected]

Tel/WhatsApp: (+86) 13757759651

Website: https://www.singi.com